Standard Axial Split Case Horizontal Single-Stage Back Pull Out

Process Centrifugal Pump

Overview

The horizontal centrifugal pump, the shaft is normally in a

horizontal position. It is sometimes overhung or placed between

bearing design. While in case of a vertical pump is one whose shaft

is in vertical position.

1. Through a suction flange the liquid flows through the suction

hub into the rotating impeller.

2. The pump shaft absorbs mechanical energy from electric motor,and

turn the electric energy into mechanical energy.

3. The blades fixed on the shaft exert a force on the fluid and

increase its angular moment, so the pressure and absolute speed

increase.

4. Consequently energy is being transferred to the fluid.

Features

WD series anti-corrosion and wear-resistant horizontal centrifugal

pump adopts the current general structure: bracket support and rear

door form, which make the pump disassembly and maintenance safe and

convenient, and the maintenance and repair cost is low.

WD series pump adopts integral casting impeller. The pump body

adopts wide flow channel design, which makes the pump adaptable to

the working conditions and has strong pump passing ability. It is

especially suitable for high solid content, high viscosity and easy

crystallization medium. It has high efficiency and excellent

anti-cavitation performance.

The bearing body adopts an axially movable structural design, which

can adjust the axial clearance between the auxiliary impeller and

the packing chamber without disassembling the pump.

Application

Phosphoric Acid Plants: H3PO4, H2SO4, HF and their mixtures with or without solid (gypsum)

up to 40% conc.

Caustic Soda Plants: Chlorinated brine, conc. HCL, Dilute H2SO4 etc.

Gas Wsahing Plants: Scrubbed liquids containing CL2, BR2, F2, I2, SO2, SO3, CO2, NH3

Gases etc. with solids replace hastalloy.

Alkali and Inorganic Salts: ammonia-alkali method, ammonia brine mother liquor produced by

the combined alkali method, caustic alkali, caustic alkali,

chloride and hypochlorite produced by the membrane alkali and

ion-exchange membrane process, alkali sulfide, sulfate, hydrogen

peroxide and the like.

Technical Parameter

model | Clean Water Performance |

flow (m3/h) | head (m) | speed (r/min) | maximum efficiency (%) | NPSH (NPSHr) m | pump head weight KG | shaft component |

40WD-250 | 8-20 | 15-28 | 1450 | 39 | 0.6 | 141 | 45 |

40WD-310 | 8-40 | 23-42 | 1450 | 45 | 1 | 257 | 55 |

40WD-350 | 8-45 | 35-54 | 1450 | 37 | 1 | 271 | 55 |

50WD-250 | 10-30 | 15-28 | 1450 | 40 | 0.7 | 146 | 45 |

50WD-310 | 15-60 | 25-42 | 1450 | 45 | 1.1 | 262 | 55 |

50WD-350 | 15-70 | 35-54 | 1450 | 50 | 1.1 | 286 | 55 |

50WD-400 | 20-75 | 50-75 | 1450 | 45 | 1.1 | 483 | 70 |

65WD-250 | 30-70 | 15-28 | 1450 | 48 | 1.1 | 149 | 45 |

65WD-310 | 30-90 | 25-40 | 1450 | 57 | 1.4 | 274 | 55 |

65WD-350 | 40-100 | 35-54 | 1450 | 59 | 1.5 | 280 | 55 |

65WD-400 | 50-120 | 45-75 | 1450 | 55 | 1.7 | 495 | 70 |

65WD-450 | 50-120 | 70-95 | 1450 | 52 | 1.7 | 524 | 70 |

80WD-250 | 70-100 | 15-25 | 1450 | 61 | 1.5 | 153 | 45 |

80WD-310 | 70-120 | 25-40 | 1450 | 62 | 1.7 | 288 | 55 |

80WD-350 | 70-160 | 35-52 | 1450 | 65 | 2.0 | 295 | 55 |

80WD-400 | 70-160 | 50-75 | 1450 | 62 | 2.0 | 500 | 70 |

80WD-450 | 70-160 | 70-95 | 1450 | 60 | 2.0 | 539 | 70 |

100WD-310 | 100-150 | 20-38 | 1450 | 65 | 1.9 | 293 | 55 |

100WD-350 | 100-220 | 35-50 | 1450 | 65 | 2.5 | 299 | 55 |

100WD-400 | 100-220 | 40-72 | 1450 | 65 | 2.5 | 529 | 70 |

125WD-310 | 120-260 | 18-36 | 1450 | 67 | 2.8 | 304 | 55 |

125WD-350 | 120-300 | 35-50 | 1450 | 68 | 3.2 | 307 | 55 |

125WD-400 | 140-350 | 45-70 | 1450 | 70 | 3.4 | 559 | 70 |

125WD-450 | 150-360 | 65-90 | 1450 | 67 | 3.6 | 741 | 80 |

150WD-310 | 200-400 | 18-35 | 1450 | 72 | 3.8 | 332 | 55 |

150WD-350 | 200-450 | 15-48 | 1450 | 75 | 4.2 | 333 | 55 |

150WD-400 | 200-450 | 40-65 | 1450 | 73 | 4.2 | 597 | 70 |

150WD-450 | 200-500 | 60-80 | 1450 | 67 | 4.5 | 753 | 80 |

200WD-350 | 300-600 | 28-47 | 1450 | 79 | 5 | 583 | 70 |

200WD-430 | 300-650 | 50-65 | 1450 | 75 | 5.2 | 765 | 80 |

250WD-350 | 400-900 | 26-45 | 1450 | 79 | 6.5 | 850 | 80 |

250WD-430 | 400-900 | 50-61 | 1450 | 75 | 6.5 | 910 | 90 |

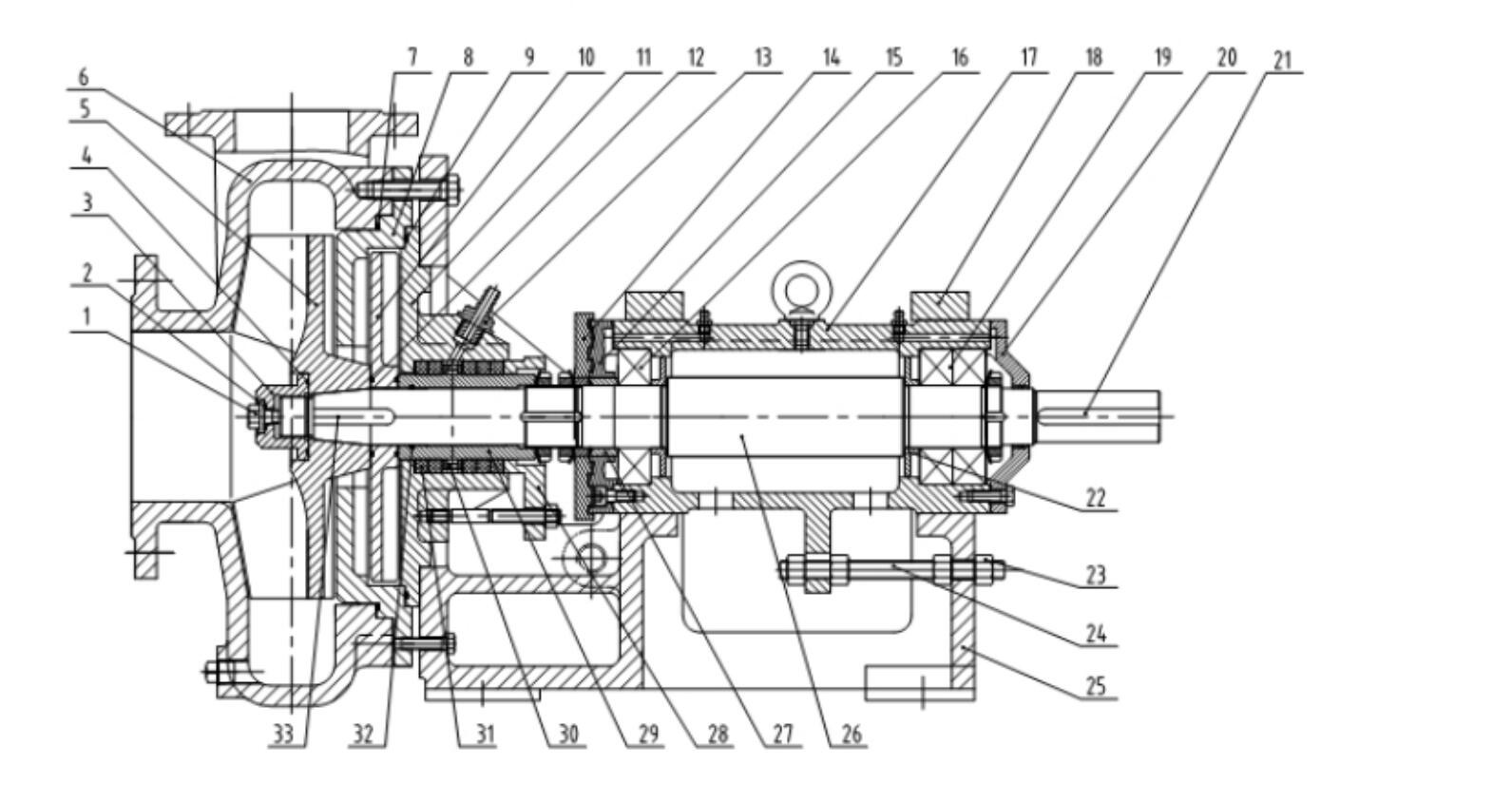

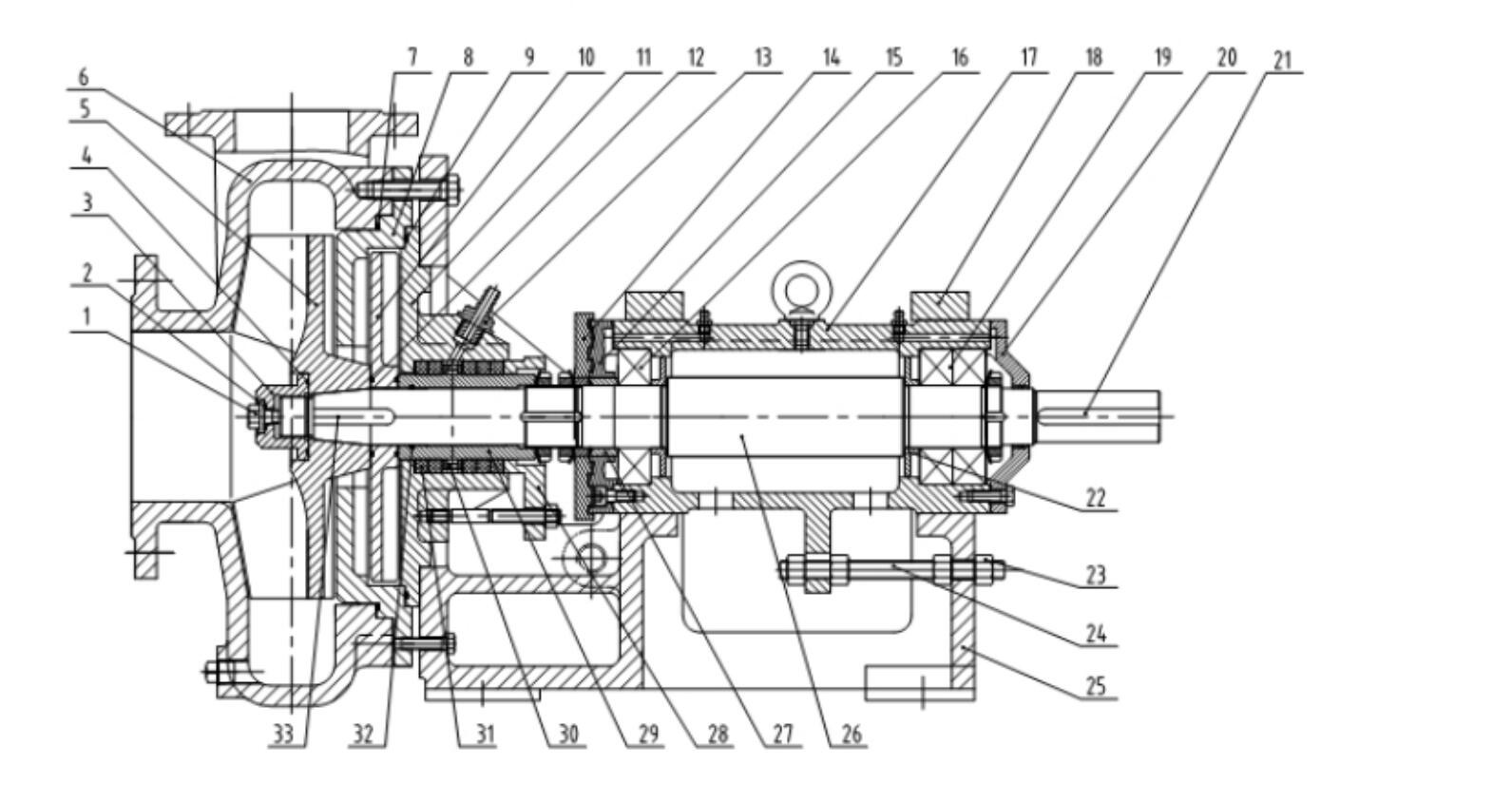

Structure

| *1 | Locking screw | *8 | Vice impeller chamber | 15 | Front bearing cap | 22 | Oil pan | *29 | Sleeve |

| 2 | Gasket | 9 | O-ring | *16 | Front bearing | 23 | Adjustment nut | 30 | Water seal ring |

| *3 | Impeller nut | *10 | Vice impeller | 17 | Bearing body | 24 | Adjustment screw | 31 | Filler |

| 4 | O-ring | *11 | Packing chamber | 18 | Bearing bracket | 25 | Bearing body bracket | 32 | O-ring |

| *5 | Impeller | 12 | O-ring | *19 | Rear bearing | *26 | axis | *33 | keys |

| *6 | Pump body | 13 | Rinse water nozzle | 20 | Rear bearing cover | 27 | Shield cover | | |

| 7 | O-ring | 14 | Water retaining plate | 21 | Key | 28 | Packing gland | | |

More Details

Pump Case:

1. high temperature annealing

2. no cracking

3.no defomation

4. guaranteed for ten years

Bearing:

1.select material

2.quality assurance

3.less friction

4.more efficient

Impeller:

1.various types of impeller

2.high permeability

3.corrosion resistance and wear resistance